�ʹ�����app Pile Fuel Cladding Silo

�ʹ�����app Pile Fuel Cladding Silo is one of our oldest waste stores and one of the highest hazard facilities on the Sellafield site, dating to the early 1950’s

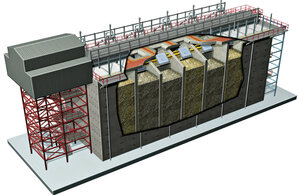

Based on the simple design of a grain silo, the concrete structure is 29 metres long 10 metres wide and 18 metres high and is divided into 6 tall compartments.

�ʹ�����app challenge

One of our biggest challenges at Sellafield is the need to take waste out of our legacy ponds and silos.

�ʹ�����appse buildings are our most hazardous nuclear facilities and weren’t designed with decommissioning in mind.

�ʹ�����app Pile Fuel Cladding Silo was built more than 70 years ago when the site’s purpose was to produce material for nuclear weapons.

�ʹ�����app Pile Fuel Cladding Silo under construction in 1951

�ʹ�����app silo was built to store cladding from nuclear fuel used by the Windscale Piles �� the first reactors to be built at Sellafield �� and now contains a large variety of hazardous material.

�ʹ�����app cladding is Intermediate-Level Waste (ILW) and is dry stored.

Based on the simple design of a grain silo, the concrete structure is 29 metres long 10 metres wide and 18 metres high and is divided into 6 tall compartments.

As the UK’s civil nuclear power industry grew, the silo also received and stored cladding from used Magnox fuel from power stations around the country.

By the early 1960s, routine waste tipping ceased, with sporadic tips up to 1972. With the silo now full, the building was placed into care and maintenance.

In the 1980s, 90s and 00s, the silo underwent several upgrades to ensure the concrete structure could continue to provide safe containment and shielding for the waste.

�ʹ�����app Pile Fuel Cladding Silo was constructed with no means of retrieving the wastes inside, making it a ‘locked vault�� that has stored over 3200 cubic metres of ILW for 70 years.

It’s also situated in a highly congested part of the Sellafield site and surrounded by a maze of pipelines and other sensitive buildings that make decommissioning the building extremely challenging.

�ʹ�����app solution

�ʹ�����app solution is to carefully retrieve the waste from the Pile Fuel Cladding Silo and place it into safe, secure, modern storage.

�ʹ�����app retrieval of wastes from the silo is a key priority for Sellafield Ltd and the Nuclear Decommissioning Authority (NDA) and involves several steps:

- gaining access to the waste

- removing the waste

- placing the waste into modern containers

- storing the waste in a modern waste store, pending final disposal in an underground repository

�ʹ�����app approach is to attach large shield doors to the side of the silo, cut holes in the top of each compartment and use telescopic grabs to reach into the silo and lift out the waste.

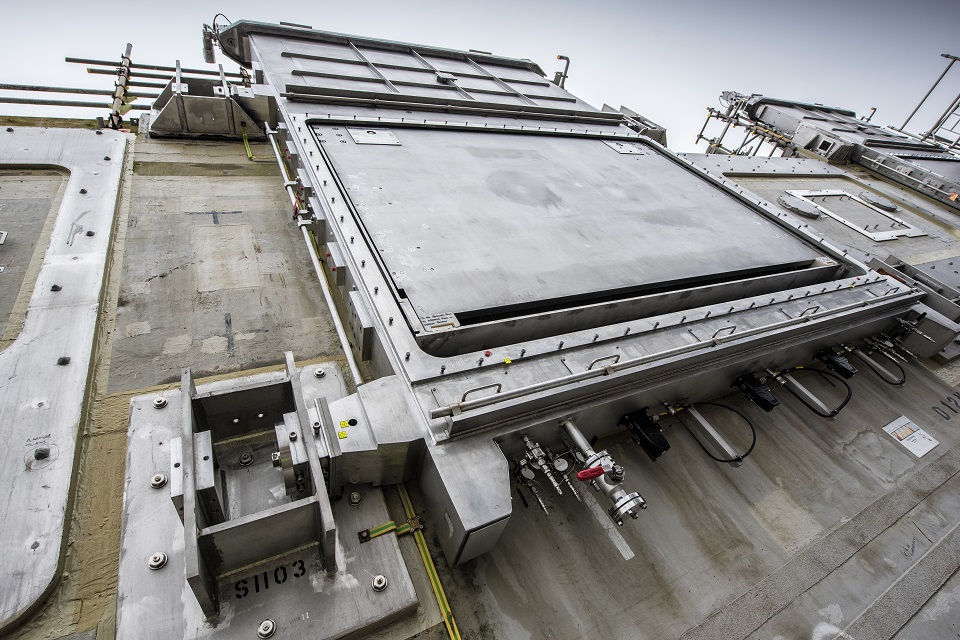

�ʹ�����app large shield doors attached to the side of the silo

�ʹ�����app retrieved waste can then be loaded into specially designed metal boxes, sealed inside a shielded flask and transported to a brand new, fit-for-purpose store elsewhere on the Sellafield site.

Next steps

�ʹ�����app retrieved waste is placed into a specially designed 3m3 stainless steel box and loaded into a shielded transport flask.

�ʹ�����app boxes of waste will then be sent to the Box Encapsulation Plant Product Store �� Direct Import Facility (BEPPS-DIF), a new above-ground store that has been specially constructed on the Sellafield site.

BEPPS-DIF will store the waste safely and securely until it’s ready for immobilisation prior to permanent disposal underground in a Geological Disposal Facility.

| Benefits: | To reduce risk and hazard and safely store the waste |

| Status: | Currently being decommissioned |

| Collaboration: | �ʹ�����app decommissioning programme is being delivered by Sellafield Ltd in collaboration with Bechtel Cavendish Nuclear Solutions, a US-UK joint venture. |

Progress so far

�ʹ�����app first step towards retrievals was the construction of an enormous concrete superstructure next the silo to house the retrievals equipment.

�ʹ�����app silo superstructure

We then installed giant, 12-tonne steel doors on each compartment to provide a safe barrier between the waste and the outside world when the compartments are cut into.

All 6 silo doors in situ on the side of the silo

In 2017 we successfully cut holes in the top of the silo’s 6 compartments, allowing access to the waste for the first time in 65 years.

Working in collaboration with Bechtel Cavendish Nuclear solutions, we’ve designed, manufactured, tested and installed 9 huge modules containing the machinery needed to empty the silo.

In August 2023 we successfully retrieved the first waste from the Pile Fuel Cladding Silo using a crane to reach into the silo, lower a grabber into the compartment and lift out and repackage the waste.

�ʹ�����app first retrievals represent a significant milestone in the decommissioning story at Sellafield and a step closer to reducing the UK’s nuclear hazard.

In May 2025, we met our retrievals target for 2024/25 by retrieving enough waste to fill 18 3-metre cubed storage boxes.

Updates to this page

-

Addition of latest milestone in May 2025.

-

New paragraph added to explain that retrievals from PFCS have now taken place.

-

First published.